GCE India Pvt Ltd opening ceremony has been conducted on 17th May 2011 at the Head Office and Service Centre in Benson Town, Bangalore. By this latest investment the GCE Group is now directly present at India, providing best support to already existing customers and to increase its market share substantially on short term. GCE India Pvt Ltd is 100% owned by GCE Group.

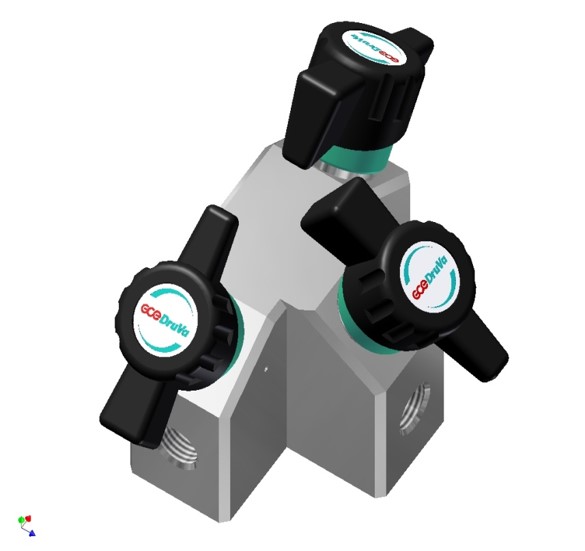

DruVa Series 500

Specifications

Cylinder and Line pressure regulators, Panels for one and two cylinders:- Single- or dualstage design

- Barstock Brass NiCr or Stainless Steel SS 316 L

- Hastelloy diaphragm

- Inlet pressure (max.)

- 700 psi (50 bar)

- 3300 psi (230 bar)

- 4300 psi (330 bar)

- Various regulator types

- General-purpose version

- Subatmospheric model

- Ultralow downstream pressure

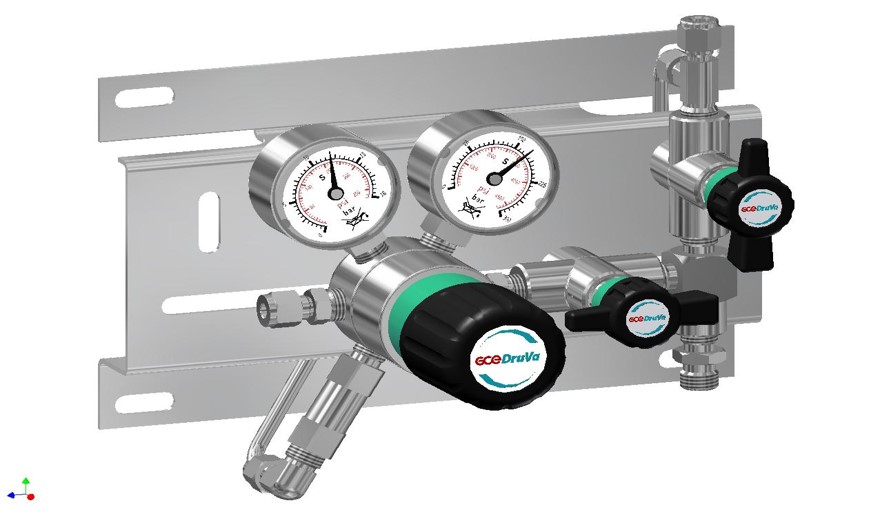

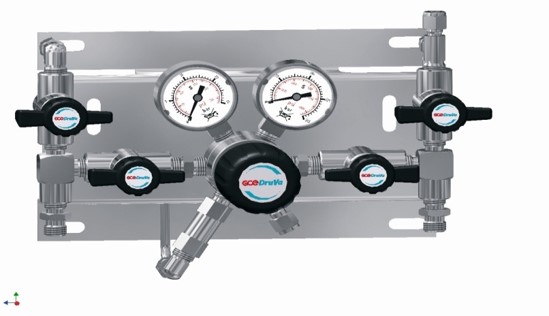

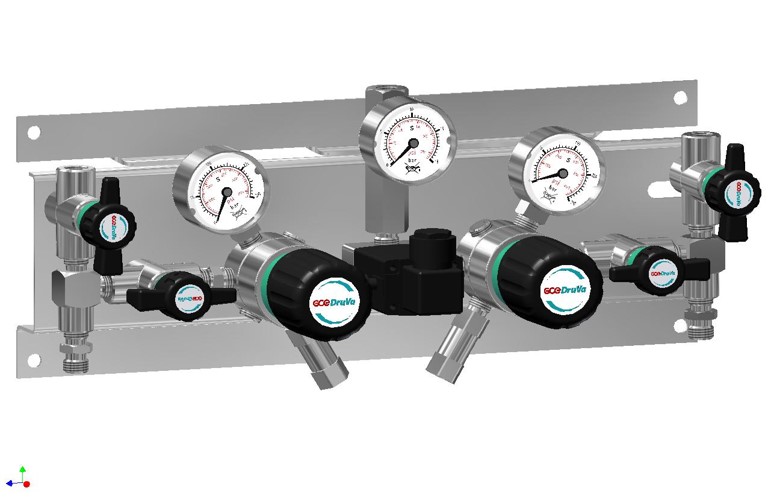

Line 500 Panels

Specifications

Single cylinder manifolds- Various purge systems

- Optional low pressure warning

- Pre-shut off valve to reduce purge volume

- Assembled on SS-brackets

Line 500 Panels

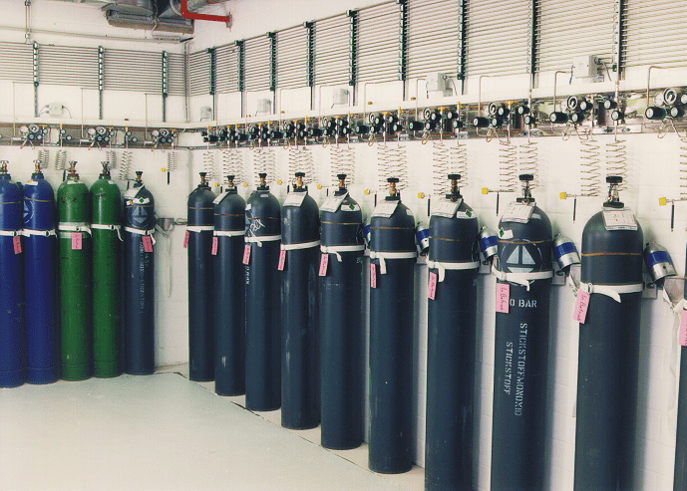

Central Gas Supply

Advantages

- Quick overwiew on all cylinders

- Reduced quantity of cylinders - less charge for renting

- Centralized storage, access for trained persons only

- Reduced possibility of missuse

- Reduced risk of accidents, as there is no need to handle gas cylinders inside the work place

Series 400

Features

- Modular design

- Various assembly situations for

- Frontplate assembly

- Furniture integration

- Suspended version

- Countertap assembly

- Gas specific colour-coded handwheels

Lab 3100

Features

- Proven components (diaphragm, damping system, regulating valve)

- Regulator with integrated shut-off function

- New metering valve with shut-off function

- 100 um inlet filters (metal sieves, not sintered discs)

- SS316L, Brass (Ni/Cr) from barstock

- G ¼“ female threads arround the body, G3/8“ female axially

- Safety gauges acc to EN 837 with bar/psi (others on request) dual scale

- Durable indication of inlet/outlet ports

- 100% product tracebility by individual serial number

- 100% Helium leak testing

Valves

Valves

- Shutoff- or metering types

- Metal-diaphragm design

- Straight or angular version

- Multiturn or 90° handwheel function

Quality features

Optical inspection of all capsule parts

GCE-HP cleaning procedures

GCE-DruVa cleaning procedures

2-step deburring of gas wetted surfaces

GCE-HP preassembly of valves & regs

Leakage Test

Long term tests

Pure Gas Systems

Quality features

- All valves and regulators are manufactured from full material.

- All valves and regulators have diaphragm of Hastelloy C(the brass as well as the stainless steel version).

- 100%-leakage-test of all components and assembled systems.

- General use of safety gauges.

- Brackets and spiraled tubes generally of stainless steel (also the brass version)

- Inlets are integrated with filters in every valve and regulator.

- All valves and regulators are specially cleaned and suitable for ECD-applications.

- Test cycles for pure gas components and systems:

- Function control with dry nitrogen

- 12 hours compressing creep test with Helium

- Helium leak test with mass spectrometer Leakage rate below 1 x 10-9 mbar l / s Helium

- New Damping System - Leads to small closing pressure & Precise Regulation.

- Nichel/Chrome Plated Coating – Corrosion Resistant leads to long life.